Eco-friendly

Silicon, the core material of Silitex, is extracted from minerals such as sand or quartz. It is a differentiated material that can replace natural leather that cannot avoid environmental pollution or animal-ethics problems, or traditional synthetic leather made from petroleum compounds, which has toxicity and environmental pollution problems. It is a next-generation raw material that fits the trend of growing interest in environmental issues.

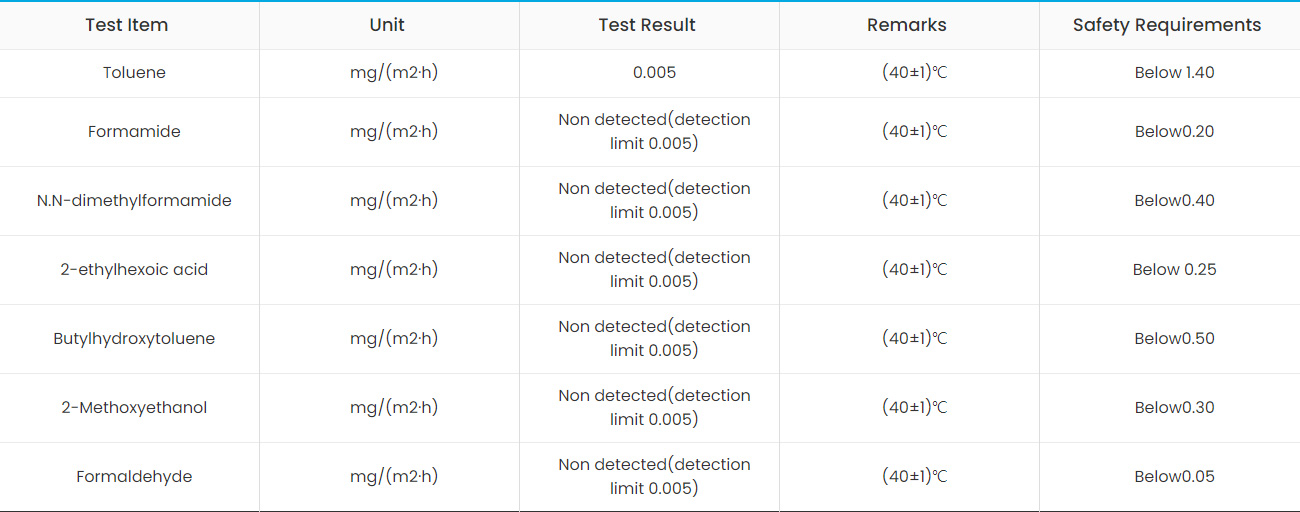

Silitex is composed only of textile fabric and 100% silicone, and it is differentiated from other types of silicone synthetic leather such as silicone oil treated PU coated surfaces. Silitex does not add organic solvents in the production process and does not emit environmental pollutants such as toxic gases and wastewater that require separate purification or management. In addition, we want to help create a healthy living environment for the consumers by using safe silicone, which is used for baby pacifiers or cooking tools

Silitex has been recognized for the reduction of harmful substances and living environment pollution and has obtained the environmental certification from the Korea Environmental Industry & Technology Institute.